Sustainability

Environmental impact in industry as well as in our personal lives is becoming increasingly important. FOX IV recognizes that improving equipment performance and efficiency is imperative to our customer's environmental goals.

FOX IV is working toward a new level of awareness with environmentally thoughtful designs, options, and corporate initiatives.

Supplier Leadership on Climate Transition

Supplier LOCT is an educational platform for suppliers, and a company collaborative for their buyers (LOCT partners). It was created to accelerate action towards reducing supply chain carbon emissions. Guidehouse facilitates an instructional seminar series with levels of progress designed to help suppliers create a greenhouse gas (GHG) emissions footprint, adopt reduction targets, disclose emissions, and explore abatement measures. The collaborative is standardizing the way forward for LOCT partners seeking to deliver on their Scope 3 climate reduction targets.

This achievement signifies our development of a Scope 3 greenhouse footprint that meets GHG Protocol and Science-Based Targets Initiative standards with the support of the Supplier LOCT collaborative. It affirms our shared ambition to reduce GHG emissions and align with industry standards.

For more information on our Scope 3 Supplier LOCT committment, contact FOX IV.

New Equipment Design

New equipment is being designed with the environment in mind. Traditional labels leave a roll of backing material that is usually tossed in the trash. FOX IV offers several equipment options that either reduce or eliminate label liner waste altogether.

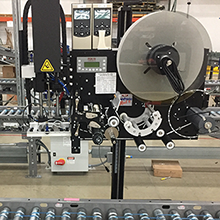

Linerless

FOX IV's Linerless label print and apply system completely eliminates label liner waste by utilizing special continuous label stock. The Linerless system prints onto the linerless label stock, cuts the label to size, and automatically applies the label to the receiving item. Additionally, because the linerless label stock uses direct thermal technology to create the print, there isn't any thermal ribbon waste either, thereby, effectively eliminating all traditional labeling waste.

FOX IV's Linerless label print and apply system completely eliminates label liner waste by utilizing special continuous label stock. The Linerless system prints onto the linerless label stock, cuts the label to size, and automatically applies the label to the receiving item. Additionally, because the linerless label stock uses direct thermal technology to create the print, there isn't any thermal ribbon waste either, thereby, effectively eliminating all traditional labeling waste.

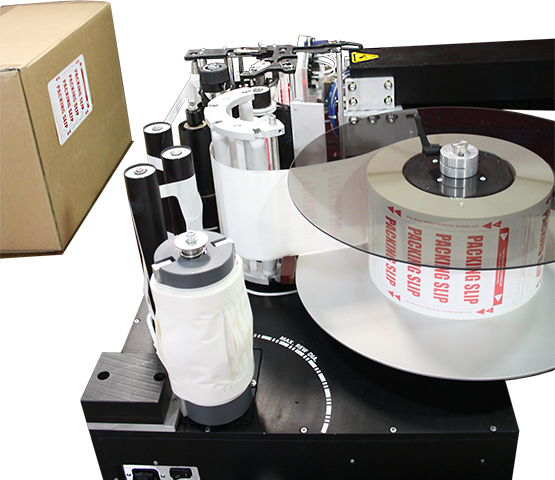

TwinPrint® Dual Sided Label Print and Apply

The TwinPrint® label print and apply system combines two processes in one. It simultaneously prints both the shipping label and packing slip on the same label. The shipping label is printed on the visible top side and the packing slip is printed on the label liner, which is cut from the label backing. The single label is applied to the shipping container packing slip side down. The contents information is concealed when applied.

The TwinPrint® label print and apply system combines two processes in one. It simultaneously prints both the shipping label and packing slip on the same label. The shipping label is printed on the visible top side and the packing slip is printed on the label liner, which is cut from the label backing. The single label is applied to the shipping container packing slip side down. The contents information is concealed when applied.

By repurposing the label liner as the packing slip, up to 60% of label liner waste is eliminated from the waste stream. Additionally, plastic waste and excess paper usage from traditional packing slip envelope systems are eliminated.

Quick Slip™ Packing Slip Print and Apply

Similar to the TwinPrint®, FOX IV's Quick Slip™ system also repurposes the label liner to become a packing slip. The Quick Slip™ features a pre-printed, visible top side that identifies it as the packing slip while concealing the contents information underneath on the label liner. It has the same environmental benefits as the TwinPrint® with the elimination of liner and traditional packing slip waste.

Similar to the TwinPrint®, FOX IV's Quick Slip™ system also repurposes the label liner to become a packing slip. The Quick Slip™ features a pre-printed, visible top side that identifies it as the packing slip while concealing the contents information underneath on the label liner. It has the same environmental benefits as the TwinPrint® with the elimination of liner and traditional packing slip waste.

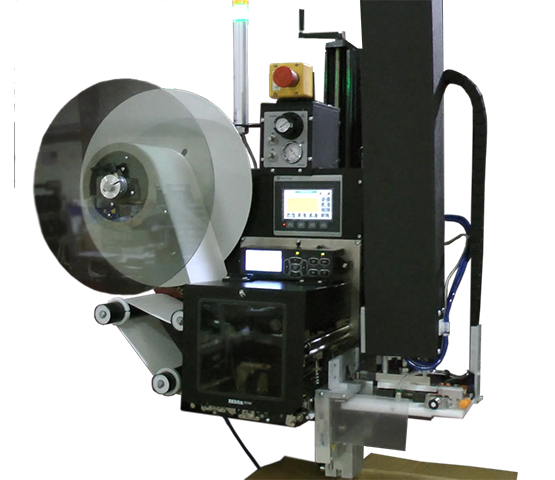

6900 Series Inserter

FOX IV's 6900 Series Inserters take a different approach to environmental impact. Instead of using a large piece of paper or labels, the Inserters print onto thin, cost effective, direct thermal tag stock, cut and insert the tag into an open top container. Because tags are cut to size, waste from label gap material as well as label liner and ribbon waste are completely eliminated.

FOX IV's 6900 Series Inserters take a different approach to environmental impact. Instead of using a large piece of paper or labels, the Inserters print onto thin, cost effective, direct thermal tag stock, cut and insert the tag into an open top container. Because tags are cut to size, waste from label gap material as well as label liner and ribbon waste are completely eliminated.

Efficiency Options

In addition to equipment design, FOX IV offers optional features and equipment to decrease energy consumption. Electric application assemblies are available for traditional print and apply systems to reduce the use of factory air. Electric application assemblies include cylinder/tamp, merge/wipe, and vacuum belt.

Another efficiency option for traditional pneumatic labeling systems is an air flow monitoring system. This system monitors the air usage of the labeling system to regulate and report on the air usage. With this system, companies can then adjust air usage to optimal levels and reduce energy consumption.

Corporate Initiatives

In addition to equipment design and efficiency options to minimize energy usage and waste, FOX IV as a company is doing their part by continually adding and evaluating programs to reduce our environmental impact. Our company wide recycling initiative targets several materials including cardboard, electrical components, plastics, and scrap metal including turnings from our machining operations. FOX IV also reuses shipping material whenever possible. Items such as boxes and packing material may be used for outgoing shipments of parts, labels, or other such products.

Our "lights out" policy seeks to reduce our electric consumption by encouraging employees to turn off light sources when areas are unoccupied, such as offices and cafe areas, and unplug energy consuming equipment when not in use. We also ensure proper disposal of oils and municipal waste.

Future initiatives include the installation of a compressed air monitoring system in our plant to monitor and adjust factory air usage to increase overall efficiency.